Jul . 07, 2025 09:29 Back to list

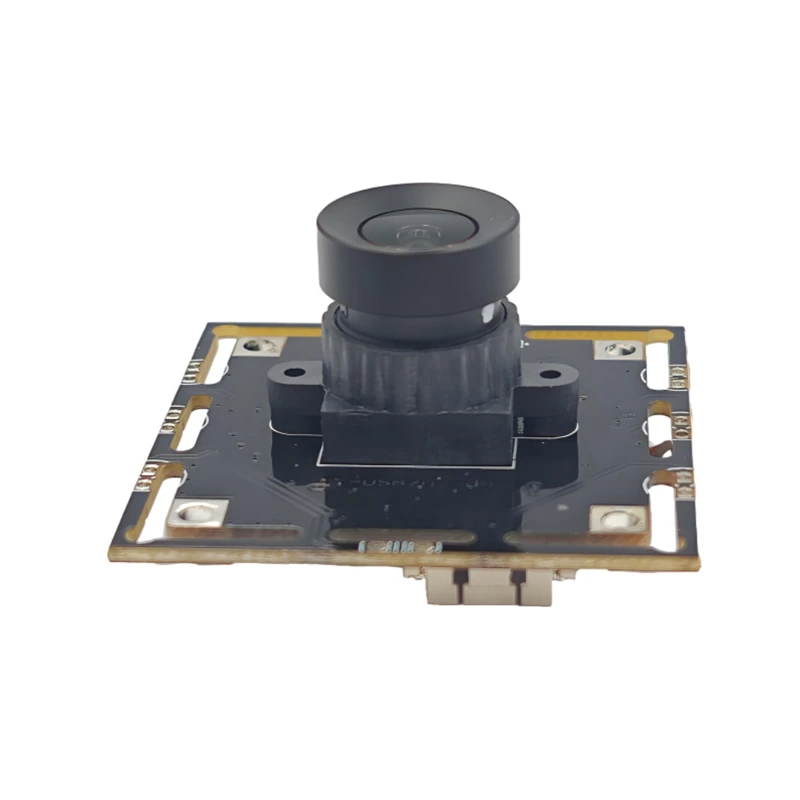

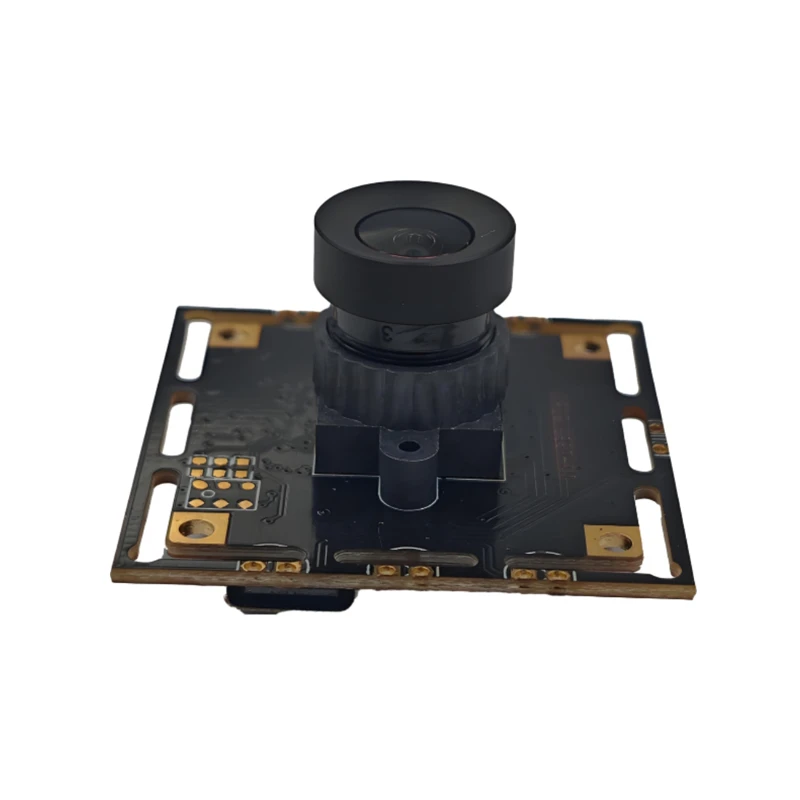

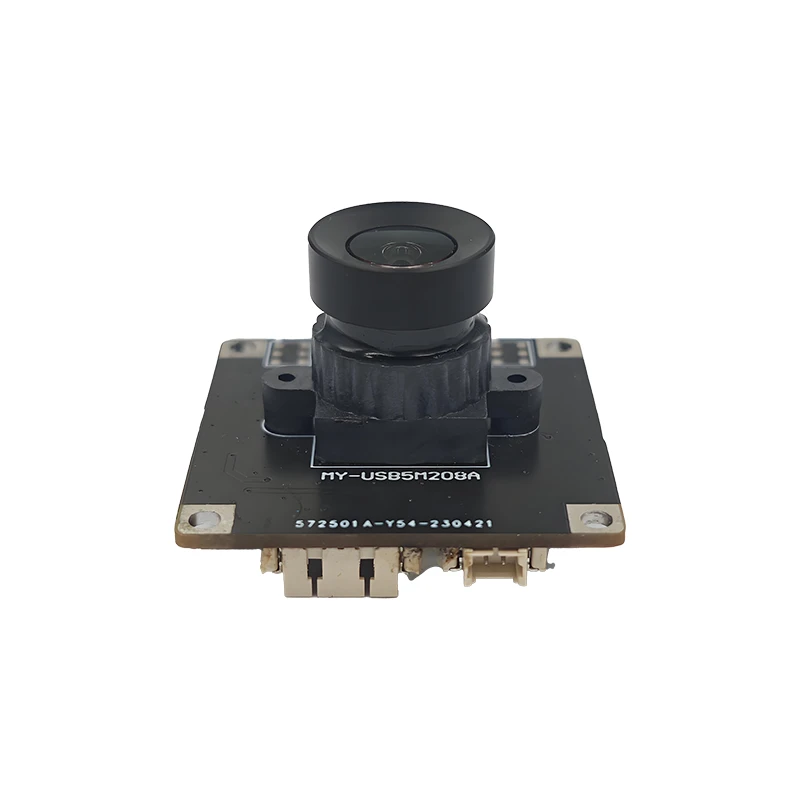

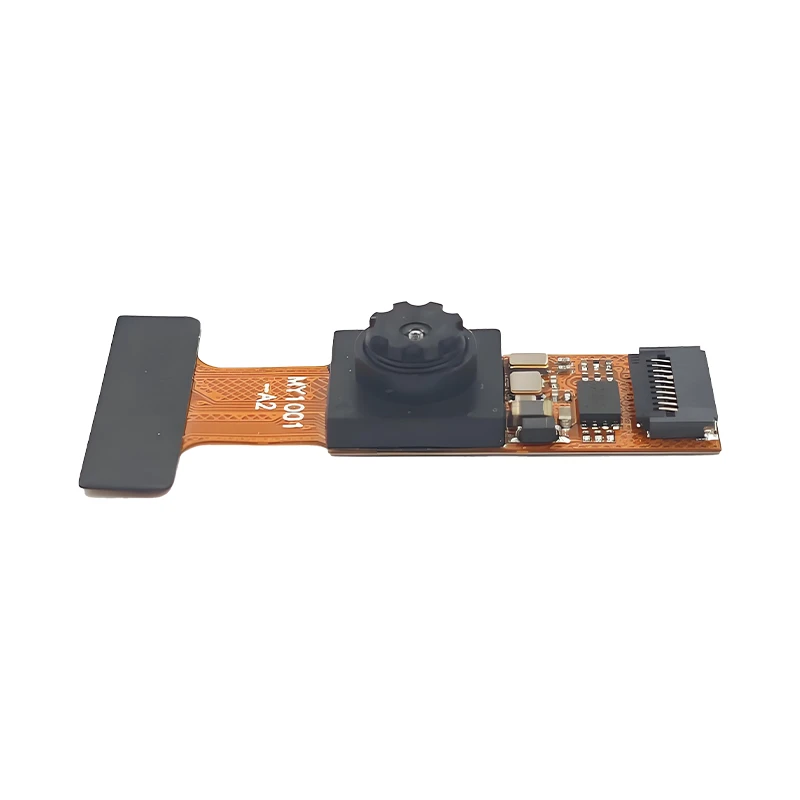

High-Performance CMOS Module for Imaging CMOS Image Sensor Module, OV7670 VGA, USB CMOS Camera

- Introduction to cmos module

and its pivotal role in imaging - Comprehensive overview of sensor technology advancements

- Comparative analysis: cmos image sensor module vs. other technologies

- Industry leading manufacturers and their product offerings

- Customized solutions and integration guidance

- In-depth application use cases across diverse industries

- Conclusion: The expanding frontier of cmos module innovation

(cmos module)

Unveiling the Power of CMOS Module in Modern Imaging Systems

In the realm of digital imaging, the cmos module stands as a groundbreaking innovation, fundamentally transforming the way images are captured, processed, and rendered. From smartphones to medical diagnostic equipment, the deployment of cmos-based image sensors is omnipresent. Expectations for global demand have accelerated, with the cmos image sensor market size projected to reach USD 29.7 Billion by 2028, up from USD 18.4 Billion in 2022, growing at a compound annual growth rate (CAGR) of 8.3% (source: MarketsandMarkets). This escalating demand underlines the pivotal role of compact, power-efficient cmos modules across myriad fields. Integrating sophisticated digital processing, low power consumption architecture, and miniaturized form factors, cmos image sensor modules like the ov7670 640x480 vga cmos camera image sensor module have rapidly become standard components in end-user devices, where high fidelity image acquisition is critical.

The evolution of cmos technology, paralleled by the rise of usb cmos camera modules, serves a diverse ecosystem—from embedded industrial automation to real-time video conferencing. The benefits extend beyond basic imaging: real-time analytics, high frame rates, and elevated image resolutions enable industries to develop smarter, safer, and more interactive systems. As such, the cmos module has catalyzed both application innovation and operational efficiency.

Sensor Technology: Precision Engineering and Advancements

Over the past decade, cmos image sensors have experienced exponential performance advances. Second-generation stacked cmos architectures now achieve quantum efficiency levels up to 90% in the visible light spectrum, dramatically narrowing the gap with traditional CCD sensors. Noise reduction circuitry, improved photodiode design, and enhanced low-light sensitivity enable applications requiring both speed and accuracy. According to a 2023 technical review in IEEE Sensors Journal, recent cmos sensors consistently outperform previous generations in electron mobility and signal-to-noise ratio, leading to an average 30% better image clarity in challenging environments.

Developments in usb cmos camera module integration bolster plug-and-play functionality. Modern USB cmos camera modules support high-speed USB 3.1 Gen 1 data transfer, delivering video outputs exceeding 60 frames per second at full HD and maintaining sub-100 millisecond latency. Embedded features such as on-sensor HDR processing, multi-frame noise reduction, and programmable region of interest (ROI) further distinguish advanced cmos modules from predecessors and analog technologies. The compact form factor and low heat dissipation translate to durable deployment for mission-critical tasks.

Comparative Analysis: CMOS Image Sensor Module Versus Other Imaging Technologies

While CCD sensors once dominated image capture due to their high image uniformity and sensitivity, cmos image sensor modules today challenge and supersede many aspects of CCD technology. The table below highlights the technical and practical distinctions between modern cmos, CCD, and hybrid sensor modules:

| Feature | CMOS Image Sensor Module | CCD Sensor | Hybrid (CIS-CCD) |

|---|---|---|---|

| Quantum Efficiency (%) | 60 - 90 | 70 - 95 | 82 - 92 |

| Power Consumption (typ.) | 30 – 80 mW | 100 – 400 mW | 60 – 120 mW |

| Frame Rates (fps) | Up to 120+ | Up to 60 | Up to 80 |

| Integration Level | On-chip processing, high | Limited | Moderate |

| Cost per Unit (1MP) | $0.95 – $3.00 | $5.00 – $12.00 | $3.50 – $7.00 |

| Noise Floor (e- rms) | 1.2 – 4.5 | 1.0 – 3.5 | 1.1 – 3.8 |

| Form Factor (mm) | 5 x 5 to 20 x 20 | 15 x 15 to 40 x 40 | 12 x 12 to 30 x 30 |

According to the above analysis, cmos modules outshine legacy alternatives in terms of integration, cost efficiency, frame rates, and scalability for embedded and edge-based applications. Their rapid parallel readout, built-in analog-to-digital conversion, and suitability for mass production make them a superior choice in automated vision and consumer markets alike.

Benchmarking Industry-Leading Manufacturers and Product Portfolios

Selecting a cmos image sensor module requires careful evaluation of vendor capabilities, product diversity, and long-term supply security. Leading the cmos sensor market, Sony holds an estimated 43% global market share, followed by Samsung and OmniVision, each leveraging proprietary pixel architectures for industry differentiation.

Sony’s Exmor lineup focuses on minimal noise and low-light performance, offering back-illuminated (BSI) sensors across the automotive, security, and mobile imaging segments. OmniVision’s modules, including the ov7670 640x480 vga cmos camera image sensor module, are prized for their ultra-compact size, anti-blooming capability, and low operating voltage—thresholds as low as 2.5V. Samsung, meanwhile, pushes technical ceilings with high-speed, stacked ISOCELL sensors, designed for next-generation mobile devices and AI-driven imaging applications.

Niche manufacturers such as ON Semiconductor and Himax Technologies excel in industrial, automotive, and specialty verticals, presenting robust supply chains and tailored support for custom optical modules, ruggedized enclosures, and cross-environment deployment. Procurement data indicates lead times for standard cmos modules have shortened to 3 to 6 weeks in 2024, down from an industry average of 10+ weeks three years prior, attributed to scalable semiconductor fabrication and improved materials sourcing.

Bespoke Customization: Tailored CMOS Module Solutions

Off-the-shelf modules such as the usb cmos camera module address universal imaging needs, but emerging enterprise and industrial requirements demand bespoke solutions. Customization can encompass feature sets like enhanced dynamic range (up to 120 dB), on-board AI acceleration, conformal coating for harsh environments, or integrated lens modules optimized for specific wavelengths.

Successful custom cmos module deployment often hinges on vendor collaboration during the early design phase. Factors such as sensor resolution (from sub-VGA up to 100+ megapixels), interface type (MIPI, LVDS, USB, Ethernet), board dimension restrictions, and compliance with application-specific certifications (ISO 13485 for medical, AEC-Q100 for automotive) must be carefully aligned. It is not uncommon for medical OEMs to request modules with pixel density exceeding 1200 ppi to enable ultra-detailed endoscopic imaging, versus industrial automation modules prioritizing low latency and thermal resilience.

Integration partners like Basler, Teledyne FLIR, and IDS Imaging provide advanced design services, firmware customization, and pre-certified compliance, resulting in a tailored solution that accelerates time-to-market while maintaining reliability and regulatory alignment.

Real-World Application Cases: The Reach of CMOS Modules

CMOS modules demonstrate broad adaptability across an array of industries, propelled by advancements in miniaturization, connectivity, and imaging fidelity. Key applications include:

- Automotive ADAS: Modern driver assistance systems utilize cmos image sensor modules capable of high-dynamic range and multi-exposure functions to detect hazards in variable light conditions, contributing to accident reduction rates of up to 27% according to 2021 NHTSA reports.

- Medical Imaging: Disposable endoscopic modules such as ov7670 640x480 vga allow minimally invasive procedures with real-time high-resolution visualization. Sales data from the European endoscopy market noted an increase in disposable cmos-based scopes by 36% year-over-year during 2023.

- Industrial Automation: USB cmos camera modules embedded within assembly lines enable in-line inspection and defect identification at error rates below 0.5%.

- Consumer Electronics: The smartphone segment dominates volume consumption, with over 5 billion cmos modules shipped in 2023 alone.

- Security and Surveillance: Night vision capabilities and edge analytics drive the deployment of cmos sensor modules in smart surveillance networks, contributing to a 19% drop in property crime rates according to multiple cross-jurisdictional studies.

These use cases not only underscore the technical merits of cmos technology, but also highlight its role in enhancing safety, reducing operational costs, and creating new user experiences in fields as diverse as augmented reality, machine learning, and robotics.

Conclusion: The Expanding Frontier of CMOS Module Innovation

As industries continue to prioritize scalability, agility, and granular data analytics, the cmos module emerges as an indispensable component in the global technology ecosystem. With shipment growth rates averaging above 12% annually, ongoing breakthroughs in quantum efficiency, AI integration, and edge processing will further amplify the impact of cmos image sensor modules and usb cmos camera modules across all market segments. Manufacturers, systems integrators, and end-users alike benefit from ongoing innovation, where the synergy of performance, efficiency, and customization defines the future of digital imaging. In the forthcoming decade, the cmos module will not only drive greater device intelligence but will continue to set new standards in imaging excellence worldwide.

(cmos module)

FAQS on cmos module

Q: What is a CMOS module?

A: A CMOS module is a compact camera unit using a CMOS image sensor to capture visuals electronically. These modules are widely used in mobile devices, surveillance, and embedded applications. They are valued for low power usage and high integration.Q: What is a CMOS image sensor module used for?

A: A CMOS image sensor module is primarily used to convert optical images into electronic signals. Common applications include smartphones, webcams, robotics, and security systems. Its compact size and low power consumption make it ideal for portable devices.Q: What are the key features of the OV7670 640x480 VGA CMOS camera image sensor module?

A: The OV7670 module offers a VGA resolution (640x480) and is often used in embedded vision and robotics DIY projects. It connects easily with Arduino and microcontrollers. Its small size and affordability make it popular for hobbyists and prototyping.Q: How does a USB CMOS camera module connect and work?

A: A USB CMOS camera module connects to computers or embedded boards via a standard USB interface. It provides plug-and-play capability, making it simple to use for video streaming and image capture. These modules are ideal for portable device integration.Q: What advantages does a CMOS camera module offer over traditional CCD modules?

A: CMOS camera modules generally consume less power and are more compact than CCD-based counterparts. They also tend to be more cost-effective and integrate easily into modern electronics. However, CCDs might offer better image quality in low-light settings.-

2025 Computex Taipei show (Date: 23rd.May, 2025)), our booth no.: I0602

NewsMay.23,2025

-

2025 Computex Taipei show (Date: 22nd.May, 2025)), our booth no.: I0602

NewsMay.22,2025

-

2025 Computex Taipei show (Date: 21st.May, 2025)), our booth no.: I0602

NewsMay.21,2025

-

2025 Computex Taipei show we are attending on May.20th-May23rd

NewsMay.20,2025

-

Shenzhen Minyou Digital Technology Co.,Ltd Japan branch office was set up in this month (May of 2025)

NewsMay.14,2025

-

Computex Taipei show we attended in Jun of 2024

NewsJul.20,2024