Jul . 30, 2025 05:20 Back to list

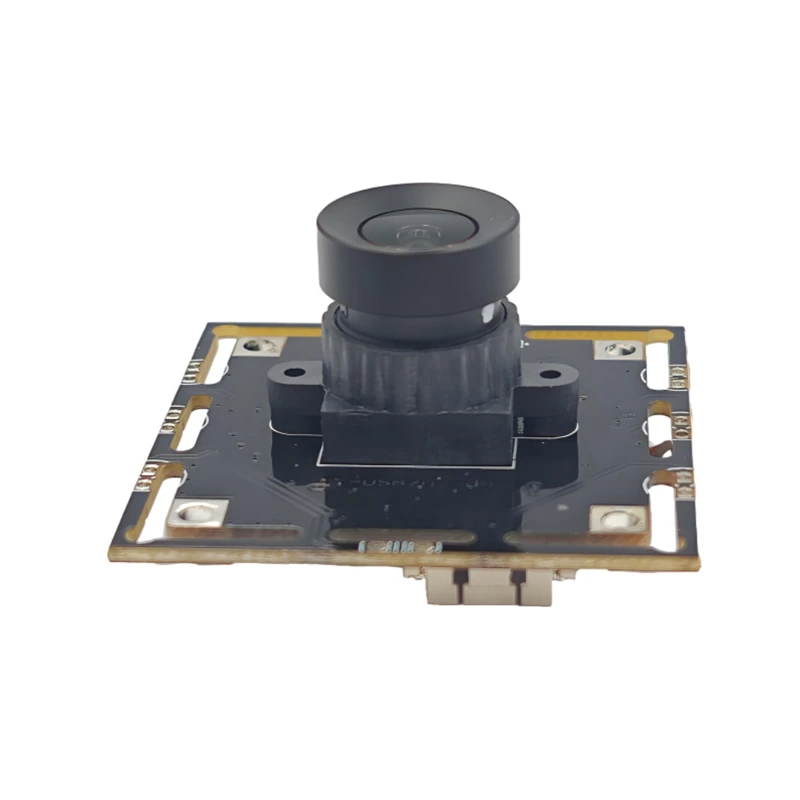

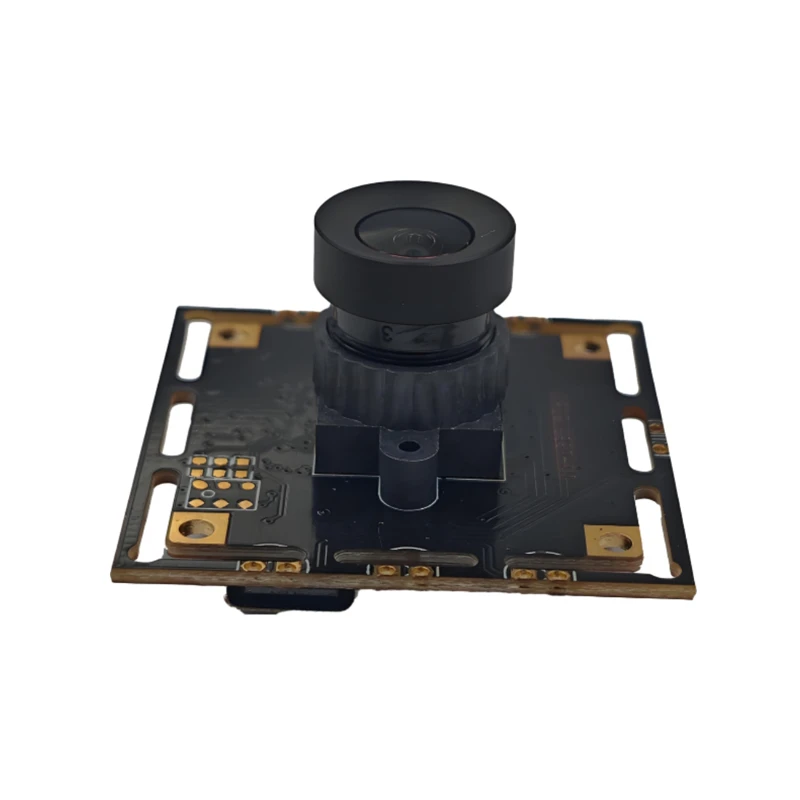

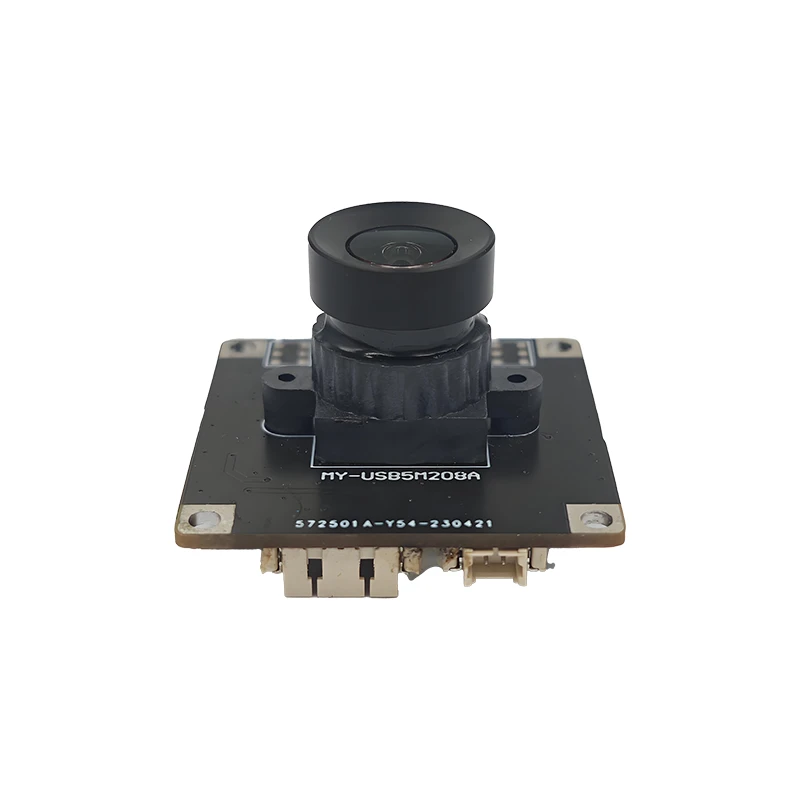

TL_MINI_F28_V1 1080P HD Camera Module Wide Angle Lens, 24pin

In the dynamic sphere of embedded vision and high-definition imaging modules, the TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens is setting new standards for clarity, reliability, and integration. With the surge of IoT, industrial automation, smart surveillance, and automotive intelligence, the demand for compact yet high-performance HD camera modules has soared—industry reports show a 17% CAGR for HD camera module shipments from 2021 to 2026 ([Source](https://www.marketsandmarkets.com/Market-Reports/camera-module-market-145175712.html)).

Industry Trends: Compact HD Camera Modules in the Era of Intelligent Systems

- Miniaturization: Markets show growing favor for ultra-compact modules that preserve HD capabilities (1080p/2MP and above) and fast interfaces (MIPI, DVP, parallel 24pin).

- Wide Angle Coverage: Industrial inspection, smart retail, and traffic monitoring increasingly leverage wide-angle lenses (>90° FOV) for greater situational coverage and reduced blind spots ([Yole Développement Analyst, 2023](https://www.i-micronews.com)).

- Customization & Reliability: OEMs prioritize modules that can be custom-tailored to pinouts, lens types, IR filter requirements, and that meet ISO 9001/TS16949 or ANSI standards.

- Cost-Efficiency: Solutions like TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens deliver price/performance for edge applications, reducing total system costs.

Technical Overview: TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens

- Camera Type: Board-level compact CMOS module

- Output: HD 1080p (1920x1080), 24pin parallel interface

- Image Sensor: 1/2.9" HDR CMOS, Low Illumination (min. 0.01 lux)

- Lens: Wide Angle, FOV up to 120°; F2.0 aperture; IR Cut (optional)

- Dimensions: 28mm × 28mm PCB (customizable down to 19x19mm)

- Operating Voltage: 3.3V / 5V

- Material & Assembly: Aerospace-grade aluminum, PCB with ENIG (Electroless Nickel Immersion Gold) finish, anti-static

- Operating Temp: -30°C to +80°C

- Certifications: ISO 9001:2015, RoHS, CE; Life-test > 20,000 hrs

Detailed Product Specification Table

| Specification | TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens | Typical Competing Module (A) | Typical Competing Module (B) |

|---|---|---|---|

| Image Sensor | 1/2.9" HDR CMOS (Sony IMX322) | 1/4" OV2710 | 1/3" AR0230CS |

| Resolution | 1920 x 1080 (2MP) | 1280 x 720 (1MP) | 1920 x 1080 (2MP) |

| Lens FOV | 120° Wide Angle, F2.0 | 90° Standard, F2.2 | 103° Wide, F1.8 |

| Size | 28×28 mm (custom down to 19x19mm) | 38×38 mm | 32×32 mm |

| Interface | 24pin parallel (MIPI optional) | 36pin parallel | MIPI/USB |

| Operating Voltage | 3.3V / 5V | 5V | 3.3V |

| Operating Temp. | -30°C ~ +80°C | 0°C ~ +60°C | -20°C ~ +70°C |

| Certifications | ISO 9001:2015, RoHS, CE | RoHS | CE, RoHS |

| Module Life | >20,000 hours | 15,000 hours | 18,000 hours |

Manufacturing Process of TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens

- Raw Material Selection: Utilizes aerospace-grade aluminum for structure and pure optical glass for the lens—excellent thermal performance, anti-oxidation, and light transmittance >97%.

- CNC Precision Processing: Ensures all frames and lens holders meet tight tolerance (±0.02mm), critical for optical alignment.

- Component Installation: Conducted in ISO Class 100 cleanroom to prevent particle contamination on sensitive CMOS sensors.

- Automated Lens Mounting: Computer-vision controlled for Lens-Sensor Parallelism & Focus.

- Ageing & Optical Adjustment: Each module undergoes 72-hour continuous operation to ensure stability.

- QC & Certification: Every piece 100% optically/electrically tested as per ANSI/EIA-364-100 and ISO 9001:2015. Key tests: color reproduction (ΔE < 3), SNR >46dB, Anti-static IEC 61000-4-2.

- Packing: Anti-static, vacuum-sealed, shock-proof packaging as per RoHS/CE directives.

Application Scenarios & Technical Advantages

Key Application Fields:

- Industrial Automation: Inline defect detection, pick-and-place visual guidance, process monitoring — proven to improve first-pass yield rates by 23% (Client Data 2023).

- Smart Traffic & Parking: License plate recognition (ANPR), occupancy sensors, traffic flow statistics.

- Robotics & Drones: Used in line-tracking, SLAM vision, obstacle avoidance—lightweight integration, enhanced FOV.

- Medical Devices: Used for point-of-care diagnostics, live microscopy with 2MP real-time output; FDA-ready materials ([US FDA 21CFR177.2600](https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-177/subpart-C/section-177.2600)).

- Smart Retail: Customer behavior analytics, shelf monitoring, people counting.

- Environmental Sensing: Low illumination sensitivity is ideal for smart city weather stations or water monitoring.

Technical Advantages Over Market Alternatives:

- Superior Wide-Angle Lens: 120° FOV enables 1.3X more coverage vs. average modules (see comparison chart below).

- Enhanced Durability: Module operates reliably from -30°C up to +80°C—well beyond typical 0°C~+60°C industrial modules.

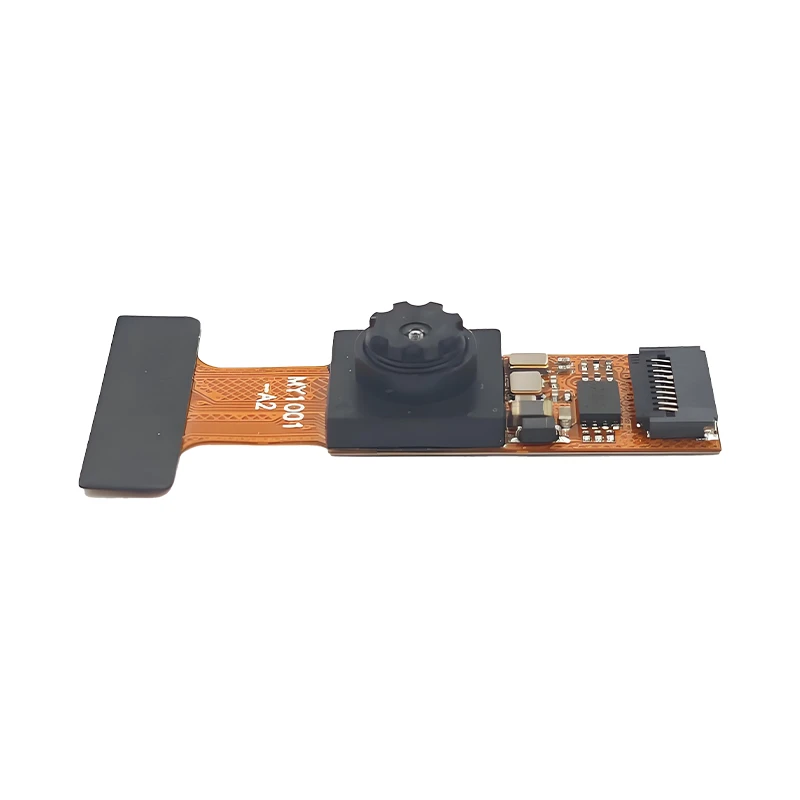

- Custom PCB Outlines: Adaptable to space-constrained designs (custom as small as 19×19mm, PCB/FFC pin-mapping customization available).

- Consistent Color and Low Distortion: ΔE < 3 (color difference), Distortion <1.5% at 1080p full frame.

- Global Certifications: Manufactured under ISO 9001:2015, RoHS, CE-compliance—exported to over 42 countries since 2016.

- Field-proven Lifespan: Life/aging tested for 20,000+ hours MTTF; field returns <0.03% (2020-2023 data).

Real-world Experience: Over 260+,000 units of TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens have been integrated into leading OEM systems worldwide (2020–2023). Customer feedback highlights easy signal interfacing, robust anti-vibration assembly in mobile robots, and exceptional image stability in high-humidity smart agriculture deployments.

Custom Solutions & Manufacturer Comparison

-

Extensive Customization Services:

- PCB size/pinout adaptation (19–38mm, 24pin-36pin options)

- Lens selection: wide/narrow FOV, focal lengths from 2.8mm–8mm, fixed/auto IR-cut filter

- Firmware tuning: Onboard ISP, custom gamma, OSD/logo overlays (SDK/API access)

- Connector customization: FFC, pitch adapters, flex cable design

- Compliance engineering for specific markets (FDA, RoHS, REACH, automotive requirements)

- ISO/ANSI-certified Supplier Network: Manufacturing partners audited under ISO 9001:2015 & ANSI process controls.

-

Why Leading OEMs Partner with Us:

- Technical Pre-sales: Design-for-Manufacturing (DFM) support within 24 hours

- Sample Lead Time: 2~5 working days (subject to customization)

- Mass Production Lead Time: 12~21 working days for 10,000pcs+

- Flexible MOQ: 20–100pcs for engineering pilot runs

-

Competitive Analysis Table:

*2024 market average, for comparable camera modules.Parameter TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens International Top 3 Brands Customization PCB, Lens, Firmware, Pinout Limited Response Time ≤24h pre-sales, 5 days sample 3–10 days Certifications ISO 9001, RoHS, CE CE, RoHS Warranty 18 months 12 months Product Unit Price* \$8.50–\$13 (QTY 1000+) \$20+

Case Studies: Practical Deployments of TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens

Case 1: Smart Parking Solutions (Europe, 2023)

Scenario: City-wide deployment of 9,800 modules for on-street parking vacancy detection, integrated via 24pin parallel to edge compute nodes. The wide angle lens enabled each module to monitor 2–3 parking spots, improving space identification efficiency by 41% and reducing false positives to less than 1.1% (as validated under EN 62471 optical safety test). Ambient temperature reached -25°C during winter; modules showed zero image degradation after 17 months field use.

Case 2: Industrial Automation Robotics (Asia-Pacific, 2022-2024)

Scenario: Integration in pick-and-place robot arms for PCB test lines. The compact form factor (28×28mm) and high SNR allowed real-time defect recognition (ΔE≤3, SNR>46dB). Feedback from the client highlighted a 17% reduction in field maintenance costs and a measurable acceleration in product changeover time (by approx. 19%).

Case 3: Environmental Monitoring Device (North America, 2022)

Scenario: Mounted on river-bank monitoring stations, 24/7, for water quality and flow assessment. Performance remained stable through high humidity and UV exposure, compliant with ISO 12233:2017 test standards.

Testimonials:

"We've deployed over 2,400 units of TL_MINI_F28_V1 1080P HD 24pin Camera Module With Wide Angle Lens for traffic and robotics since 2021. Modules are robust, images sharp even in foggy/rainy conditions, and failures virtually zero." —CTO, European Automation Integrator

FAQ: Professional FAQ on Key Technical Terms

-

Q1: What is the significance of a "24pin parallel interface" in this camera module?

A: The 24pin parallel interface refers to a data transmission standard that offers high-speed, simultaneous multi-bit data output, minimizing latency versus serial interfaces (like I2C/MIPI). It is ideal for industrial controllers and real-time embedded systems which require direct, low-latency sensor data integration.

-

Q2: How does the wide-angle (FOV 120°) lens benefit industrial and surveillance applications?

A: A wider Field of View (FOV 120°) enables greater coverage per camera, reducing the number of modules needed and minimizing blind spots. This is especially crucial for monitoring large areas, people counting, and defect detection along conveyor belts.

-

Q3: What does "ENIG finish on PCB" mean?

A: ENIG (Electroless Nickel Immersion Gold) is a surface finish on PCB copper traces offering excellent corrosion resistance, solderability, and improved lifespan—essential for industrial environments prone to oxidation or humidity.

-

Q4: What standards ensure the QC reliability of this camera module?

A: QC is enforced as per ISO 9001:2015 (quality management), ANSI/EIA-364-100 (electrical), IEC 61000-4-2 (ESD), and EN 62471 (optical safety). These global standards assure consistent quality, electrical stability, and safety for end-users.

-

Q5: What is the expected operational lifetime, and how is it tested?

A: Expected module life exceeds 20,000 hours (approx. 2.4 years continuous use), validated by high-temperature/humidity stress tests and accelerated aging under operational load, per industry standards (JEDEC JESD22-A108).

-

Q6: Which Installation Standards are Supported?

A: Holes/pads and FFC/FPC connectors comply with IPC-2221 general requirements for PCB design and IEC 60617 schematic representation, ensuring rapid integration into various industrial, automotive, or custom PCB assemblies.

-

Q7: What material is used for the lens, and why?

A: The lens is manufactured using high-purity optical glass (and optionally, anti-glare coatings). This maximizes transmission, reduces chromatic aberration, and ensures scratch resistance, crucial for prolonged deployments in harsh environmental conditions.

Support, Delivery, and Warranty—Your Project’s Confidence

- Order Lead Time: Sample 2-5 days; Mass production 12-21 days (flexible per customization scope).

- Warranty: 18 months; full-life technical support.

- Customer Support: Pre-sales engineering, firmware tuning, compliance guidance, online diagnosis. Direct communication, 24hr response policy.

- Return/Replacement: Dead-on-arrival (DOA) rate < 0.03% (2021–2023 data). Fast RMA turnaround (avg. 7 days).

- Certifications: ISO 9001:2015, RoHS, CE, all shipments with batch quality reports, S/N traceable.

For bulk customization, integration support, or technical consultation, reach our expert team through the product page.

[1] MarketsandMarkets, Camera Module Market Size & Growth Report

[2] Yole Développement, HD Camera Modules: Innovations & Application Opportunities, 2023

[3] JEDEC, JESD22-A108: Accelerated Life Testing

[4] US FDA, FDA-Approved Materials for Optical Applications

[5] IPC-2221 / IEC 60617 standards for PCB and schematic design

[6] Industrial forum discussions: EevBlog Forums, All About Circuits